Friday, 4 May 2012

Wooden legs as cat legs

These are pretty much the polypropylene chair model but instead of using maya to add the wood colour and texture i have just photoshopped them in for the simple fact I am more comfortable with photoshop. I will Only be making one board with this chair in it and it will be the same as the board for the polypropylene. I dont feel I need to make a completely different board just because of one material change as the general idea of the product is the same.

Wednesday, 2 May 2012

Few Renders

Looking at Different woods

One of the ideas that came from chatting with my tutor was that the legs could possibly be wooden and attached to the polypropylene seat. So i started looking at different woods and there properties.

One thing i was fully sure about was that I wanted the legs to be a dark colour so black or grey would be the first choices.

I firstly thought of using black ash wood for my product . I like the colour and texture of it but the only problem it had was that it was very easily decayed (maybe not a instant problem but still). I am also not sure of how heavy it can be but the wood I do use needs to be strong durable and light.

I then looked at walnut which was the wrong direction. Its a heavy wood and does not look great if i am honest and is used for carved decorations then for solid furniture.

I then looked at walnut which was the wrong direction. Its a heavy wood and does not look great if i am honest and is used for carved decorations then for solid furniture.

I then came across beech. It receives different stains and finishes well and is used in to make light furniture so that is a bonus. I like the texture and I think it would be strong and durable but....

Birch is all the qualities i want to have for the legs and I already know it is well tested and used in furniture manufacture. The company IKEA use this wood a lot in there products which is a big thumbs up to the wood being good.

I will still stain it black till its close to the colour of the polypropylene, fiberglass seat. The legs will be attached using screws and the fitting its self is already part of the chair injection molded chair.

This is the texture i will be using and then colour i would like it to be or as close to as possible.

One thing i was fully sure about was that I wanted the legs to be a dark colour so black or grey would be the first choices.

I firstly thought of using black ash wood for my product . I like the colour and texture of it but the only problem it had was that it was very easily decayed (maybe not a instant problem but still). I am also not sure of how heavy it can be but the wood I do use needs to be strong durable and light.

I then looked at walnut which was the wrong direction. Its a heavy wood and does not look great if i am honest and is used for carved decorations then for solid furniture.

I then looked at walnut which was the wrong direction. Its a heavy wood and does not look great if i am honest and is used for carved decorations then for solid furniture. I then came across beech. It receives different stains and finishes well and is used in to make light furniture so that is a bonus. I like the texture and I think it would be strong and durable but....

Birch is all the qualities i want to have for the legs and I already know it is well tested and used in furniture manufacture. The company IKEA use this wood a lot in there products which is a big thumbs up to the wood being good.

I will still stain it black till its close to the colour of the polypropylene, fiberglass seat. The legs will be attached using screws and the fitting its self is already part of the chair injection molded chair.

This is the texture i will be using and then colour i would like it to be or as close to as possible.

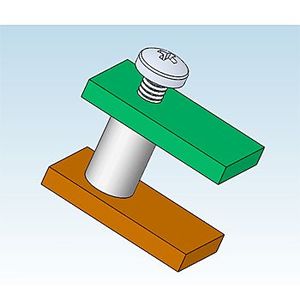

How do the wooden legs stay in

The wooden version of the chair as i have explained will be fixed to the bottom of the seat. The actual part that holds the leg will part of the injection molded piece. This saves on making more components. The leg will be held there by push screws (metal ones of course) that will go through the leg. This is a nice simple solution and could also be painted or coloured black to blend in with the chair possibly.

Tuesday, 1 May 2012

3D Model= Now comes with curve!

I have now remodeled the chair to include the curve where the sit and back join up. It does look a lot better i admit. I will now render it and start my boards. I have made a few choices at this point in the project.

I will be making two chair outcomes at this point in time. I am keen on my single piece polypropylene and fiberglass chair so I will firstly make them into the final boards. Secondly I will then look into the idea the legs could be a different material and then make this into a final render etc.

I am keen on both ideas and to see the outcomes.

Will the polyproplene process work ?

I have done a quick look into researching the injection process of one single piece , and if this will be strong enough and work. My findings have been informative.

To the left is the Bellini chair designed by Mario Bellini. He has made the chair using the injection molding process and the chair is a single piece, no seams no blemishes. The one difference to my idea of just using polypropylene is that the chair is a mix of both polypropylene and fiberglass. This gives added strength and durability.

From seeing this I wanted to see other mixes of materials that other designers have used.

This is the Mem chair by Kristalia. The chair is again made in injection molding and is reinforced with glass. From this description I assume its fiberglass and not just glass used. I am keen to use fiberglass to strength my own chair.

I also did come across another small piece of information.

This is the Lisboa chair designed by Jon Gaspar. Its is a single piece again that only uses polypropylene only. The process is different though using injection molding that is gas assisted. I am unsure if this makes them hollow. Either way I will be using injection molding to make a solid object.

After scrolling down I did see that the Lisboa chair is polypropylene and fiberglass.

I will now be using a mix of polypropylene and fiberglass to make my chair and using the injection molding process.

To the left is the Bellini chair designed by Mario Bellini. He has made the chair using the injection molding process and the chair is a single piece, no seams no blemishes. The one difference to my idea of just using polypropylene is that the chair is a mix of both polypropylene and fiberglass. This gives added strength and durability.

From seeing this I wanted to see other mixes of materials that other designers have used.

This is the Mem chair by Kristalia. The chair is again made in injection molding and is reinforced with glass. From this description I assume its fiberglass and not just glass used. I am keen to use fiberglass to strength my own chair.

I also did come across another small piece of information.

This is the Lisboa chair designed by Jon Gaspar. Its is a single piece again that only uses polypropylene only. The process is different though using injection molding that is gas assisted. I am unsure if this makes them hollow. Either way I will be using injection molding to make a solid object.

After scrolling down I did see that the Lisboa chair is polypropylene and fiberglass.

I will now be using a mix of polypropylene and fiberglass to make my chair and using the injection molding process.

One simple curve

After a chat with my tutor , he recommended I look ad adding a curve from the back to the seat of the chair. I have done some drawing to look at the idea and I do like it . This means i will have to do some remodeling of the chair on rhino.

We also spoke about maybe have a different material for the chair, maybe wood or metal but something to keep in tie with the cat theme. I will do two models one as a single molded piece and the other with a different material for the legs (including fixings)

I will research to make sure that the polypropylene injection process will work by looking at other products that have done this and other materials possible for the chair.

Subscribe to:

Comments (Atom)